Business

The title of 501

Babulalji Jain’s friendship with Nawab Hamidullah was well known, so it was no surprise when the Nawab conferred a personal nickname upon him. The moniker would go on to define the family and its association with the detergent industry.

The story goes that when Babulalji acquired the agency for the Tata Group in 1942, Tata Oil Mills (TOMCO) produced a popular detergent soap bar called 501, named so by TOMCO chief Jal Naoroji. A nationalist, Naoroji had felt they could do one better than the popular French detergent called 500, and so the brand 501 was born. The episode is mentioned in ‘The Creation of Wealth: The Tatas from the 19th to the 21st Century’ by R.M.Lala. The 501 brand later became a part of Hindustan Unilever’s Rin sub-brand. Babulalji continued to run the agency until 1965, with the 501 detergent bar becoming one of its most known brands.

At the time, there were several well-known men named Babulal in Bhopal. A gathering at the Nawab’s palace usually meant that most prominent personalities would be invited, and confusion would often ensue because of the common names. To mitigate this, Nawab Hamidullah gave each of them a nickname. The one given to Babulalji was 501 or Paanch Sau Ek.

This moniker accorded by the Nawab became such a part of the family identity that it is still referred to in historical and fictional books. Even today, the family considers the name a matter of pride, and the company’s phone numbers and car license numbers all end in ‘501’ or incorporate the three digits wherever possible.

Expanding business and challenges

By the time Murlidhar Jain passed away and passed the baton on to Babulalji in 1941, their moneylending business had been well-established. There was also the wholesale dealership in sugar and other commodities. But Babulalji wanted to do something fulfilling. Chandrakanta Jain recalls how, when she was young, Babulalji tried running a grocery store for a while, but didn’t enjoy it. “It’s not that it didn’t work,” she says. “But we could see his heart wasn’t in it. He was looking for something more.”

That came through a chance errand for the Nawab. Between 1942 and 1943, there was a massive shortage of rice in the state of Bhopal. The Nawab summoned Babulalji and asked him to travel to the state of Rehwa as his envoy, with a letter requesting for rice to be sent to Bhopal. The journey would be by train up till Satna and then on by coal-gas-operated bus. Once there, the letter stamped with the Nawab’s seal made entry easy for Babulalji, and he managed the transaction with ease.

Soon after, there was a shortage of ghee in the state. At the time, ghee was the primary cooking medium and cooking oils had not yet been explored. Recalling the success of Babulalji’s last mission, the Nawab once again looked to him for assistance. This time, Babulalji was sent to Bombay to find out more about a ‘vegetable ghee’ that was said to be popular among urban circles. This was vanaspati, and it was while researching it that Babulalji came across what would become the brand of his first agency – Swastik Oil. Swastik Oil Mills was owned by the Sarabhais of Ahmedabad, the company behind the first synthetic detergents in India, and were considered a quality brand.

Around the same time, he also acquired the agency for TOMCO and Tata Chemicals. Tata was, at the time, the leader in soap brands like Hamam and Moti. But their most popular offering was the 501 detergent soap. They also launched brands such as Lakmé, because of which the family was able to sample premium makeup products at a time when they were not easily available to the public.

In 1949 Babulalji also became a distributor for Hindustan Lever, a relationship that became the defining point for the family business. That brought with it the agency for brands like Brooke Bond, Red Label, Lifebuoy, Sunlight and most importantly, Dalda.

Babulal Jain, centre, top row at the Dalda Wholesalers Conference, Ujjan, 1957

During the sixties, well-known business people with influence or a public persona were chosen to represent brands in new markets, and prominent companies often chose social leaders as their distributors and stockists. In 1965, they were made stockists for both the food and chemical divisions of Hindustan Lever.

There was a time however, when Babulalji considered giving up the Hindustan Lever agency. In 1973, profits were low, at just two per cent, and the future seemed uncertain.

Chandrakanta Jain recalls the day her father made the decision. “He had left for Bombay, perhaps to discuss his options. My mother and I were at home when he called from there. He was obviously in two minds and asked her whether she thought he should drop the agency. I was sitting right next to my mother and mutely signalled to her to say no. We needed the business, as there were no plans on the horizon just then. If a new opportunity came by, we could consider letting Hindustan Lever go. I knew my father would never listen to us kids, but my mother’s opinion was important to him. I’m so glad that I spoke up and made my mother convince him to hold on. He did, and thank goodness, because our relationship with Hindustan Lever turned out to be such a wonderfully successful one.”

Babulalji Jain, while ambitious, was an astute man. Meticulous and hardworking, he was invested in the betterment of his children and society at large, and to this end, he often gave up whatever seemed to hinder that course. In 1953, he set up a dal or pulse mill in the Galla Mandi area of Bhopal, along with oil and cotton ginning mills in partnership with Murlidhar Gangan and Lala Mulkraj. Managing three mills however, especially those in partnership, proved difficult, and when his chartered accountants Renva and Company pointed out that he was being duped by his partners, he decided to step out of the partnership and focus on the agency. He did this with no regrets, and never looked back. By and large a content man, he rarely hankered after money or power.

“No one can steal from us what we are destined to have,” he would often tell his wife Badami Devi. In the mid-sixties he wrapped up the moneylending business as well, to fully concentrate on the agency.

Nevertheless, Babulalji did harbour a dream to start his own factory, and even acquired a plot in the Bhopal Industrial Area, where he planned to start a plastic sheet plant. That plan was abandoned when his eldest son Mahendra decided to leave the country for his higher education in 1969. Babulalji surrendered the plot, but continued to look for opportunities. He thought there might be one when in 1967, Hindustan Lever attempted to set up their first third party manufacturing factory in Poona. However, the Department of Industries soon stopped this and in fact, banned HL from starting any more such plants, stating the contravention of certain legalities. Babulalji didn’t lose hope. He put the word out about his interest, but continued to focus on the agency.

The ‘70s brought further challenges to running the agency. Political groups often targeted Babulalji’s business because of his affiliation to the Congress party, but he would resist the bandhs or strikes called out by them. In 1973, upon his refusal to shut down his shop during one such bandh, Jan Sangh members broke in and looted his godown. He took it all in his stride.

Babulal Jain, middle row, extreme left; Surendra Jain in a suit, middle row, extreme right; Mr Patel; R K Sawhney, bottom row, third and fourth person from left at the Redistribution Stockists’ Conference, 1973

That same year, as oil imports became very expensive, the government of India slapped regulatory prices on essential items such as soap. Soaps that were once sold for eight to ten annas were now priced at two to four annas. Supplies were low, margins were even lower. With constraints on both supply and prices, and overheads to pay, businesses suffered. Several stayed in limbo, unable to either move forward or shut shop. The restrictions were finally lifted when Hindustan Lever lobbied the government to get soap deregulated, and succeeded.

One of the most challenging times the family faced was in 1974. The Essential Commodities Act (ECA) had been enacted in 1955 to regulate the production, supply and distribution of a whole host of commodities. It had been put in place to prevent stockpiling of short-supply goods by wholesalers, retailers and importers, and to make essential products available to buyers at fair prices. The act however, was sometimes misused by the administration to harass the mercantile class.

Babulalji’s son-in-law Surendra Kumar Jain recalls the harrowing incident: “My father-in-law was a principled man, set in his beliefs. Once he was committed to a cause, it was hard to shake him, no matter who he was going up against. In 1974, he held the distributorship of Dalda in Bhopal. One day, a couple of men from the governor’s office visited the shop and asked for a tin of Dalda. Babulalji informed them politely that as a wholesaler, he couldn’t sell them a sole tin, those were the company rules. He suggested they buy a tin from one of the many retail shops around, Dalda being sold in plenty there. The men were disgruntled, but left.

A few days later, a small group of government officers arrived at the shop at around 5 pm claiming that they had orders to check Babulalji’s stock. Babulalji, confident they would find no discrepancy, asked them to go ahead. The team set about counting the soap bars and Dalda tins in the back of the store. But they found the stock in order. Seeing that Babulalji also stocked ACC cement, the men insisted on counting those bags as well.

Meanwhile, a few of the senior officials from the team sat out front on the gaddi or mattress laid out for visitors. Probably aware of what was to ensue, they tried suggesting to Babulalji that he should not wait around, and should make himself scarce. But Babulalji refused, saying he had done nothing wrong and that he had no reason to be afraid. He remained seated at the shop, waiting for the men to finish their investigation.

Eventually they found three bars of soap that had been set aside because they had been nibbled by rats. The bags of cement had been stored in a separate godown, where unfortunately, rainwater had leaked through. As a result, the cement in two hundred of the bags had set hard. Babulalji had already accounted for the ruined bags in his stock register. Still, under the pretext of there being extra soap bars that were unaccounted for, and the hardened bags of cement, Babulalji was booked under the DIR Act and arrested. At the police station, Babulalji was jailed, and faced with uncertainty, his blood pressure shot up. He was admitted to the hospital. The family, shocked by this unexpected turn of events, tried their best to have him released. His brothers-in-law rushed in from Gwalior and applied to the High Court for bail. Thankfully, the appeal was accepted and Babulalji was released on bail on the second or third day.

It was not that Babulalji had been unaware of what might happen when he refused the officials that tin of Dalda. But he was so uncompromising when it came to his principles that he was willing to face whatever would follow rather than buckle under the system.”

The early seventies having been a very troublesome time for the family, Babulalji decided it would be wise to diversify. In 1977, the family got its first Rajdoot agency in partnership, under the name Mahaveer Agencies. The showroom was inaugurated by Motilal Vora, an influential political leader who would go on to become twice Chief Minister of Madhya Pradesh. In 1985, the agency expanded to Yamaha motorcycles.

In the Bhopal riots of 1992 however, the showroom was a target of arson, and thereafter, the family retained it only until 2002.

In the 1980s there was a shortage of a great many products, and rationing was the norm. As the family held agencies for Dalda and ACC cement, Babulalji had people queuing up daily at the shop to collect their share.

Mahendra Jain recalls: “We would get a permit for the allotment of cement wagons, but long before the wagon had arrived there would be a queue of customers. There would be queues for soap and detergent. It was a time of acute shortages, and many merchants would take advantage by siphoning off material and giving customers less than their money’s worth. But my father’s reputation meant that if you bought a fifty-kilo sack of cement from him, it was likely that it would hold more rather than less its specified weight.”

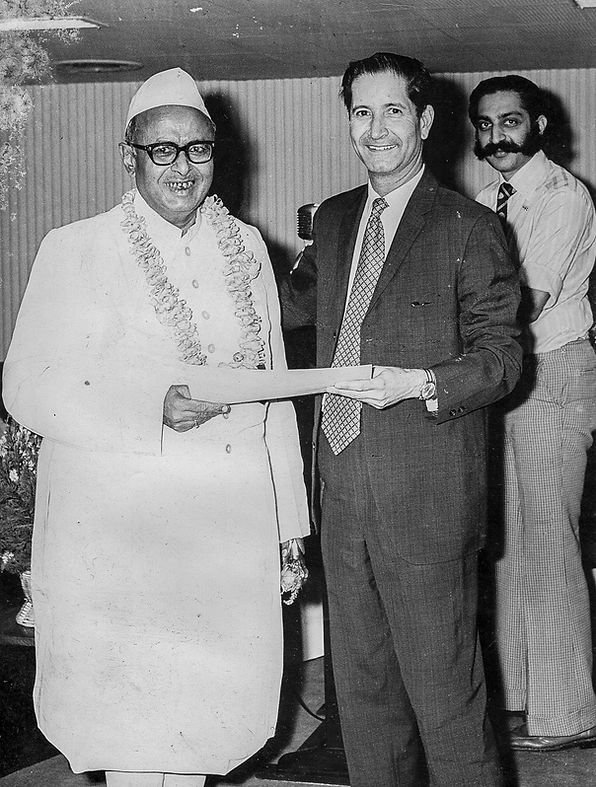

Babulal Jain with HLL Sales Director J. C. Chopra at the Silver jubilee at HLL, Bombay, 1976

Mr. Babulal Jain in the first row along with then HLL Chairman T. Thomas and Sales Director J. C. Chopra at the 25 Year Silver Jubilee Awards in Bombay, 1976

Babulalji was, at one time, one of the highest taxpayers in Bhopal, and was accorded the status and role of nagarsheth. A position stemming from Mughal times, a nagarsheth was considered the biggest and most influential merchant in a community, one who would represent the mercantile class at court and be looked upon to resolve disputes on their behalf.

After Babulalji’s death, an opportunity to set up a contract manufacturing plant came by, and Badami Devi encouraged the family to pursue it. A pragmatic woman, she realised that their existing business had limitations, and it would be impossible to sustain a growing family on it alone. It was this foresight and conviction that gave the RM Group the impetus to expand and build what has become a diversified and much stronger business today.

Agency and distribution

By the early 80s, the agency was handling the Hindustan Lever business across Madhya Pradesh. Bhopal at the time was a fascinating market for any kind of FMCG manager, and this was one of the reasons why the Rajrup Murlidhar distributorship was very significant to Hindustan Lever. Bhopal was an evolved market, one that was differentiated early on into supermarkets run both privately as well as by co-operative societies and government companies. A further advantage was that both Surendra and Sunil Jain’s long association with retailers and distributors in the area meant better business relationships. They spent enough time in the field to keep abreast of market happenings and understood ground realities. Besides, they usually knew the inside story of anything notable that happened, information that was very valuable to any company.

In their association over three generations, the RM Group has seen many changes in the leadership at the helm of Hindustan Lever.

A Hindustan lever manager says: “We have nearly four thousand redistribution stockists in every part of the country who distribute our products through more than seven hundred thousand retail outlets. A few, like the RM Group in Bhopal have been with us for more than just one generation. These are some of the shrewdest traders in the country and the most well-respected ones in their own towns. In their case, a generation gives way to another at a slower pace than that of the chairmen of Hindustan Lever. So it’s natural that they compare the current lot of sales managers, directors and chairman with preceding generations, because they have seen so many. They are polite enough of course, not to give offence to anyone – but their nostalgia is a kind of reminder that the bonds are older than the present generation in the company would know.”

Early marketing and promotion

In an era where marketing had not yet evolved, the family would take pains to plan each product launch and popularise it.

Sunil Jain had a natural talent for this, and would often come up with the most innovative ideas, such as sending processions throughout the city made up of horse carriages or camels.

During the initial years, he would have to cover three hundred villages of Madhya Pradesh – no mean feat. “There was no media or advertising and no distributors,” he recalls. “We would send out two vans laden with three hundred cartons of stock, mostly soaps. Each van would be equipped with a driver, a salesman and two helpers. They would usually return in three days.”

One of the earliest promotion drives in the villages came on the suggestion of Lever manager Mr.Dhond in 1982. Using resourcefulness, and banking on the goodwill of seventy years, Mr. Dhond believed it was possible to run a cinema van as a promotion. Sunil, just nineteen years old at the time, was tasked with getting this operation off the ground.

The plan was to have a photophone projector inside the van, along with a generator and a portable screen that would be set up outside. The team would consist of a driver, a propagandist and an operator. The first vehicle, a Premier Dodge from Nausherman and Company of Indore, was bought for Rs. 25,000. The body had to be custom-made, which was done in the compound of the Kiwi factory. Sunil had to help work out the design – where the berths would be placed, how the projector would run, and such. Mr. Dhond also connected them to the photophone projector supplier in Goa, whom Sunil travelled to meet, first going by train to Bombay from Bhopal and then catching an overnight bus to Goa. There, he visited the photophone factory to buy the projector, which he carried carefully back to Bhopal. Once the generator was bought, all the parts were in place.

Sunil recalls reading up and studying about each and every part, how the connections would work, and also the responsibility of managing and budgeting everyone’s TA & DA and salary. He recalls too, a Mr.M.N.Godbole from Hindustan Lever, who was very knowledgeable about the villages on the route and helped him design a PJP, or Permanent Journey Plan. Mr. Dhond could count every village and special market day on his fingertips, including the days on which the haat bazaar or market day was held in every village. A spool of colour film had been ordered from Bombay that had songs on it from popular Hindi movies. It was decided that the promotion would be held on the village market day from 4 pm to 6 pm near the chaupal or public square.

Once the van, which had been loaded with Lux, Lifebuoy and Breeze soaps, was parked at the chaupal, Mr. Sodhi the operator would take the stand out and load the spool. The village children would come running up and gather round the van, calling out excitedly that the ‘soap van’ had arrived! Then the propagandist Mr.Bhavsar would run the offer: Buy a bar of soap, get one matchbox free.

At 6 pm, there would be a show and a sampling. Then as soon as it got dark, they would screen the movie songs. For cost efficiency’s sake, there would be a screening at two spots in the village, one at 7 pm and one at 9 pm. After the second show ended, the men would all go and sleep in the cinema van. Two cinema vans would cover three hundred villages all the way till Raipur. Sunil Jain ran these vehicle promotions successfully in rural Madhya Pradesh for seventeen years, till 2000.

The promotion was so successful that Hindustan Lever introduced a rule that said that any salesman, sales officer or assistant sales manager who joined the company would have to spend two months in the jungle in the cinema van as part of his training. A company representative would be there with them in the van. It was a tough schedule, and if the candidate could not find accommodation in a village, he would always have to sleep in the van for the night. The idea inspired the Congress party to run similar promos of their own, and they borrowed 70-80 vans to run their election campaign. The Congress ‘video-on-wheels’ was handled by Member of Parliament J. K. Jain, who actually came all the way to Bhopal to learn how to run the operation.

A learning ground for FMCG

The Rajrup Murlidhar dealership was significant enough to Hindustan Lever that every prominent business leader in the company would make it a point to visit Bhopal and Babulalji on their travels. Chairman T.Thomas even invited Babulalji for a conference once, knowing that the RM Group had become an important centre for Hindustan Lever’s new appointees and interns to get the best hands-on training and to understand the core business and how it operated from the ground up.

The family recalls scores of new executives that would come and spend time with them on their territory, learning the ropes, guided by their insights and market feedback. Some of those who trained with them went on to occupy very senior positions in the company. One of the ex-chairmen of Hindustan Lever was Mr.M.S.Banga, who began his career in Bhopal in 1977 and was close to Surendra Jain. Mr.Sudhir Sitapati who recently became an MD and CEO of Godrej, also started as an assistant sales manager in Bhopal and trained with the RM Group.

Beyond FMCG, even Cyrus Mistry’s first official visit as the head of Tata Motors was to the RM agency. Mahendra Jain also recalls that Mahatma Gandhi’s son Ramdas Gandhi, employed by the TOMCO office at Nagpur at the time, visited them and would correspond with them through handwritten letters. The shop pattern employed by them was also used as a model by Hindustan Lever. The family’s efficient and organised way of conducting business led to establishing many such best practices at HUL.

Sunil Jain recalls how they would make detailed plans and projections even in the 1980s. “Just like how large companies today ask for a monthly plan – making a beat plan, making lists of shops in the market, fixing days of the week for each shop – this whole concept of monthly planning, all of this is taught at MBA schools now. But we’ve been doing it since the eighties.”

He continues, “So many MBA graduates are sent to Bhopal or Indore to train with the RM Group. I’ve lost count of how many people I’ve trained – at least five thousand managers. Three or four years ago,

I went to meet a sales director at Hindustan Lever, a Mr.Shrinandan Sundaram who is now Executive Vice President. As soon as we met, he said, ‘Sunilji, do you recognise me? You were the one who taught me how to count cartons of soap by the dozen. The first day of my training, you opened the carton and showed me exactly how to pick up a cake of soap, how there should be a row of six in a sequence and how they were to be stacked and displayed.’ My appointment with him was supposed to be for only fifteen minutes, but we ended up talking for two hours.”

Building business backward integration with the next generation.

In the late eighties, the powdered soap detergent Nirma had gained popularity and become Hindustan Lever’s toughest competitor in the detergent sector. In an effort to counter this, Lever bought over Stephen Chemicals with plans to start manufacture of a detergent product named Wheel.

Meanwhile, for some time, the family had been trying hard to cut a deal to set up their first outsource plant. In 1987, Mahendra and Surendra Jain met with Hindustan Lever to discuss setting up a toilet soap plant. They were turned down, and the Hindustan Lever manager suggested they open a Surf plant instead. As distributors, the brothers had their ears to the ground and knowing that Surf would not really sell, they decided against it. This knowledge of what actually sold was a useful advantage, something Babulalji brought up when he shared his grievance with his associate at Hindustan Lever, P.M.Sinha, who went on to become Director, Corporate Affairs. Sinha told him to be patient and wait till another opportunity presented itself.

This would come in the winter of 1994 with a chance conversation between Rakesh and Sunil Jain. Rakesh was at the Jumerati shop, about to pack up and leave for Ajmer, when he casually asked his uncle Sunil about an application to set up a detergent powder plant that they had submitted a few weeks earlier to Hindustan Lever. Sunil pulled out the file and immediately called his business associate Dilip Saigal, who headed sales at Hindustan Lever. Saigal informed him that they had decided to go with someone else. Instead of giving up, Sunil Jain quickly made a few calls and set up a meeting in Bombay with Hindustan Lever’s technical director, a Mr.Chadha. Rakesh immediately cancelled his plans to return to Ajmer and was sent that very night to Aurangabad to do a survey, where the plant was initially meant to be located.

They managed to get an appointment for three days later in Mumbai with the Hindustan Lever technical team at their Andheri headquarters, where Surendra, Mahendra and Sunil Jain, along with their nephew Rakesh and his father Surendra Kumar Jain, were to meet with Mr. Chadha.

At the meeting, they were surprised to learn that instead of a Wheel powder plant, this was meant to be a Wheel detergent cake plant. The investment for the latter would be almost double that of the former, which meant that instead of a CapEx of around 1.5 crore, as the brothers had anticipated, the plant would cost nearly 3 crore. Though apprehensive, the RM team showed no hesitancy. Their only condition was to request a location change from Aurangabad to Nashik. The Hindustan Lever team agreed, but only if the Jains could provide the data on proposed sites in Nashik within a week or two. The window for deciding between them and the other party that had already been finalised for the plant set-up was small.

As soon as the meeting ended, the Jains set to work. Because the meeting had been put together so late, they had driven down directly from Bhopal. There was no time to waste. Now on their way back, they dropped Rakesh off at Nashik to conduct a survey and prove that Nashik was a suitable site for the new plant. Rakesh recalls how, at the time, with little to no experience and in the absence of the internet, he had to come up with his own questionnaire and start collecting data. He spent all day visiting government offices for subsidy information, transporters’ offices for inward and outward freights, and electricity departments for rates of different industrial areas, travelling only in auto rickshaws or on foot to save costs.

Babulal Jain with HLL Sales Director J. C. Chopra at the Silver jubilee at HLL,

Bombay, 1976

The Hindustan Lever team had expected the brothers to get back to them in a couple of weeks. Instead, Rakesh Jain called them in just three days with all the necessary data. He was asked back to Bombay for an official meeting where he was quizzed on the finer details – freight, subsidy, rent, water supply, etc. The thoroughness of Rakesh’s answers convinced Lever to give the RM Group a chance. But it still took them nearly five months to finalise the deal, as the other party that had been considered earlier had to be informed of the change.

Now that they had the go-ahead, Rakesh headed back to Nashik. He needed to find sites with optimal conditions and shortlist them, and this he did by surveying every likely part of Nashik, going even so far as Waluj and Sinnar.

After three months and over a hundred potential site visits, an agency suggested looking at Dhulia as an option. Rakesh visited the MIDC office, and with the help of local industrial leader Mr.Madan Surana, they finally had the land that ticked all the right boxes. The group’s first contract manufacturing plant was underway.

While everyone was excited by this development, raising the finance for the project remained a major hurdle. The group had submitted a proposal to both the banks they dealt with at the time, the Union Bank and the State Bank of Indore, but had not yet heard from either of them. At the time, a bank manager Mr. Ashok Menon from the State Bank of India visited the Dhulia site. He was down from Bombay, looking to complete loan targets for that particular MIDC. Rakesh didn’t pay much attention to his offer, but kept his card. It would prove to be serendipitous.

Meanwhile, Mahendra Jain, keen to get the project started, would visit Dhulia every weekend. Rakesh told him of the bank manager’s visit, but having already approached their regular banks, Mahendra brushed it aside. However, to their dismay, both banks turned down their proposal. Two months had passed, but remembering the bank manager’s card, they decided to see if there was a possibility of securing a loan from the State Bank of India instead.

The meetings went off well, but there was still a long wait while the files moved from office to office. The group’s initial equity was running out and finally, Rakesh had just five thousand rupees left. The family asked him to try securing a small loan in the open market. A family friend Mr. Dwarkadas Agarwal however, advised him that it would be in their best interest not to take a loan from the open market because Dhulia being a small town, word got around, and it wouldn’t look good if the group were seen to be borrowing money before the project had even begun. To tide him over, Dwarkadas gave him a lakh as a loan. Using the money judiciously, Rakesh began to doggedly follow up on the SBI loan application. He recalls one particular meeting when his uncles couldn’t make it because of a delayed train schedule, and he ended up at the bank alone. “As luck would have it,” he says, “there was no electricity that day. I had to climb eleven floors on foot and then manage the meeting on my own.”

Finally, at the end of January 1996, the loan came through. Meanwhile, though the paperwork was being put in place, vendors had already been lining up for their payments. Not expecting much, Rakesh approached the bank to request if some payments could be made before all the formalities had been completed. To his great astonishment, the bank paid nearly fifty lakh to their vendors and cleared their dues.

In 1995 the Bhoomi Pujan was performed and work on the plant was started immediately. Rakesh stayed on site throughout and handled the project, while Mahendra, Surendra and Sunil Jain would visit whenever they could and lend a hand.

Mr. Sunil Jain attending an RS Conference at the Bombay Branch of HLL, 1983

Success and innovation at the Dhulia plant

Three key personnel ensured that the plant had the most economical layout and efficient practices, right from the start: Project Manager Rajesh Koul; Project Assistant, Ramlal Kundal; Quality Control Manager, Syed Zafaruddin, all three from HLL, were instrumental in making the plant a success. While Mr. Syed focused on quality control mechanisms, Mr. Koul had a bird’s-eye view of the entire operation well ahead of time, from production, logistics and commercials all the way to choosing the team. The two men credit the family with having complete faith in them to set up the systems right. “They were new to manufacturing, but they made up for their lack of experience with having open minds. They were ready to learn everything they needed to make this plant a success,” says Rajesh Koul.

Mr. Syed, who was given the Chairman’s award at Hindustan Lever for his work with RM Chemicals avers, “Dhulia was a very significant plant for Hindustan Lever. Anything they first wanted to implement, they would say, ‘Let’s start with Dhulia. If Dhulia delivers, we know that this product can be made anywhere.’ I’ve really seen Dhulia grow from a small starter plant to the large one it is now, with its many processes and innovations. And it’s flourished because of this family. I have trained so many other organisations as well, but RMC’s attitude, the way they accepted instruction or listened to advice showed how much they wanted to learn and grow, how honest and disciplined they were, and that motivated me to give my best. It’s a two-way process.”

A great advantage, he feels, was the fact that they had no prior manufacturing background. They were a blank slate, so to speak, and they trusted the processes and the expertise of their more experienced employees. In a way, their inexperience worked to their advantage. From process to technical, all sorts of innovations were piloted at the Dhulia plant.

-

Hazard Analysis and Critical Control Point (HACCP) is an internationally recognized system that prioritises and controls potential hazards in food production. With HACCP, an industry can better assure consumers that its products are as safe as good science and technology allows. As Hindustan Lever’s soap and detergent division began to adopt better quality management practices from the food industry, they adopted HACCP and Dhulia was the first plant where it was implemented.

-

A plant was set up in 1998 to manufacture AOS (alpha olefin sulphonate) with three levels of purity at 28 percent, 70 percent and 93 percent. HUL wanted the higher percentage, but it caused the water in the formulation to increase, so they switched to 70 percent purity. The plant also handled thermal oil heating.

-

In 2001, a new plant was set up at Dhulia to manufacture LABSA, an important active ingredient in detergent manufacture, which is usually always produced in batches. This was the first Hindustan Lever OEM plant in which LABSA was directly and continuously processed.

-

Weight control systems and automatic recording for auditing were put in place for better quality control and verification. Everything was recorded and verified so if there was a problem, it could easily be traced back to source.

-

In automated Vim bar manufacture, the bars produced were cut using a wire cutter. When the size of the bar was increased to 400 gm however, its composition changed and the bar hardened faster. The wire cutter didn’t work well with a quick-setting formula, and so for the first time a plate cutter was used, which also gave the bar a better, more even finish.

-

A magnetic sweeper was developed, which helped to sweep the shop floor of foreign particles without contaminating the actual product.

-

Often, water vapour would get into the plodder, and it resulted in bars that were too soft. A catch pot system was devised to collect the water and maintain proper penetration values.

“The Hindustan Lever team seemed to have the confidence to try newer ideas with RM Chemicals because they were keen learners and straightforward in their feedback,” says Syed. “The motto on the shop floor was, ‘Do it the first time; do it better the second time, and make a quality product at source.

Another great advantage by which they benefitted was that the manufacturing equipment was from Jubee & Sarha Engineers Private Limited in Kanpur, owned by Mr.R.K.Raina a very respected ex-HUL engineer who brought in a lot of innovation in the equipment based on his own experience of the industry.”

Knowing that the group had not handled large company production, Hindustan Lever at first commissioned just thirty thousand tons per year of Wheel soap at the Dhulia plant. The plant was run mostly manually, and processes like lifting detergent bars, laying them on racks to dry, placing them on the wrapping machine and then packing the wrapped bars into cartons was all done by hand. Eventually, as modifications were introduced, the process became increasingly automated and today, all soap is manufactured untouched by hand, on conveyor belts. The plant’s capacity has also increased from thirty thousand to sixty thousand tons.

Challenges, solutions and the development of a flourishing ecosystem

The Dhulia plant brought with it a whole new perspective not just for the family, but for the area itself. Rajesh Koul, Technical Director at R.M. Chemicals, recalls the early days. “We spent a lot of time challenging the old way of working, and for that we needed fresh minds. One of the best things we did was to bring in a group of about twenty people from the industry right at the beginning, much earlier than work on the plant actually started. They were part of the team, part of the construction, the installation, etc. At each step, they were part of the process, so they knew exactly how things had been thought out, placed and erected. Ownership increased, so the acceptances were easier and came in very early on.”

Dhulia being a relatively backward area in those times, there was not even a proper construction firm available. “We were on a shoestring budget, so we did a lot of innovation ourselves, in terms of both planning and execution,” says Rajesh Koul. “Lever would have typically spent maybe 7 to 8 crore in those days for that type of plant. But we completed it in just 2.1 crore. We hired masons and labourers from the nearby villages, and we soon realised that these people were looking to do more than just their daily jobs. So we offered them extra work, like loading and unloading raw material, or jobs at the plant itself. As the factory grew and started doing well, people began to earn a steady income, and a certain culture of discipline began to develop. It became a centre on which a lot of livelihoods depended. I think that played a big role in the success of the unit and in keeping costs down.”

Logistics was another area where the team had to think outside of the box. “Though Dhulia was at a convenient junction,” Koul says, “it had very few businesses. There were no transport companies. But there was a man who owned three or four trucks, who used to occasionally move goods from one place to another if asked. In 1998, we roped him in to work for us on a regular basis. At the time, we were handling a thousand tons in a week, and that was a huge amount for anybody in those days, especially in a place like Dhulia. Trucking began to be seen as a business opportunity by the local people of Dhulia, who realised it was something they could invest in. So Dhulia became a trucking centre. Now we sometimes handle and transport 700 tons of finished goods in a day. Similarly, there was a guy who was associated with us right from the beginning, supplying raw material that he transported in his tankers, so he grew with us and became very successful. The plant at Dhulia actually helped many families.”

Another challenge which the company faced was communication. Rajesh Koul recalls how they managed. “Telephone connectivity was very bad, and the area had no mobile connectivity. Even booking a landline in those days often meant a waiting period of ten years.

Somehow, RMC managed to transfer one or two numbers to Dhulia from Bhopal, but only after a lot of time and great effort. Before that, right from the project planning stage till even after the plant was started, we were left to our own devices.

A couple of kilometres away from us was an STD booth. Rakesh and I would make a detailed list of what needed to be done, people we needed to speak to, their names and numbers. For purchase orders and telexes, we had made an arrangement with the booth owner where he would keep all incoming faxes for us in a file and we would pay him later. Also, for faxes that needed to be sent, we would send a person with the number and the message, and the booth owner would keep the fax reports for us. So you can imagine, we would go with a big list, sit there for a couple of hours and go through every item one by one. This went on long after even the factory started because there were no lines, there were no communication systems then at all. Eventually of course, things improved.”

Koul feels the Dhulia factory changed MIDC, made it more economically attractive. “

Until the Dhulia plant was set up, there was no other activity in the area. There were a couple of other big factories but they were almost dead. The Dhulia plant initiated a process where people started believing in the area and coming to MIDC for work. It started with a tea stall, then a tyre puncture person arrived, then other small businesses and services. Small shops began appearing. Most people working at the factory, about a hundred and fifty or so, were from outside Maharashtra, from UP, Bihar and such. They rented accommodation in the nearby villages.

All of this caused a ripple effect, about 300 to 400 people started getting jobs and incomes. It actually turned the economy around, created an entire ecosystem.”

Becoming a recognised manufacturer

The factory at Dhulia was a model plant. Considerable thought had gone into designing the space in such a way that it was possible to make a quality product at a low cost without cutting corners, and this effort was not lost on Hindustan Lever. The company would proudly display the factory to visitors, and even shot footage to showcase at the Annual General Meeting that year.

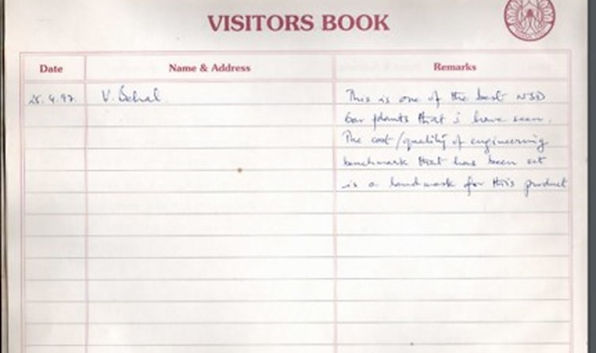

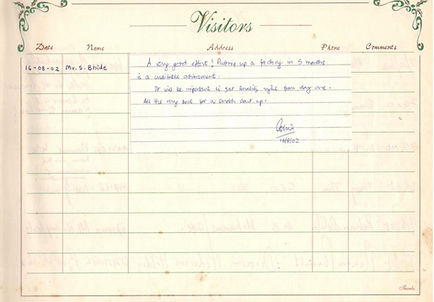

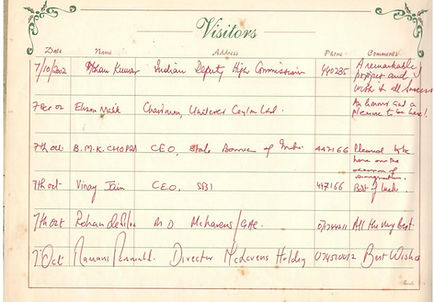

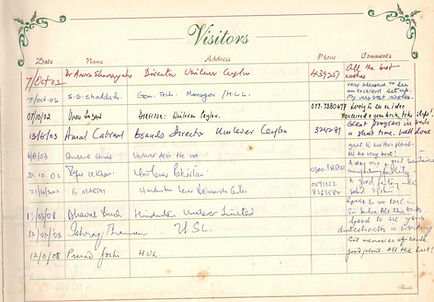

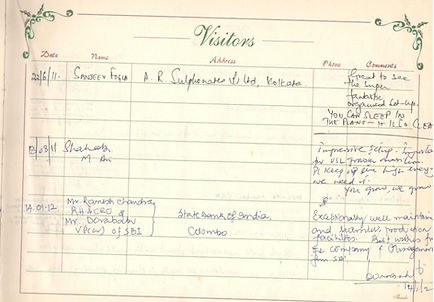

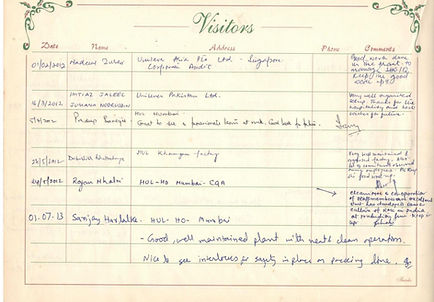

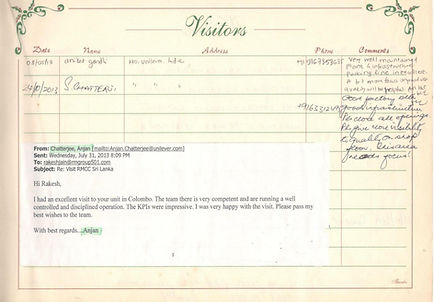

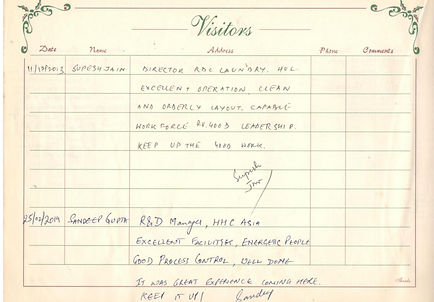

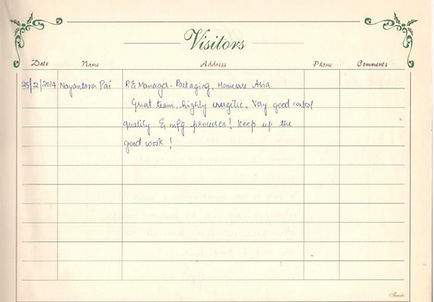

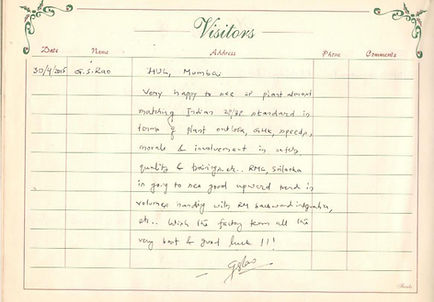

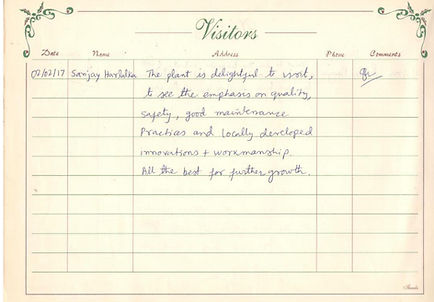

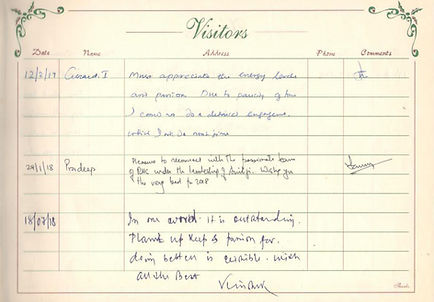

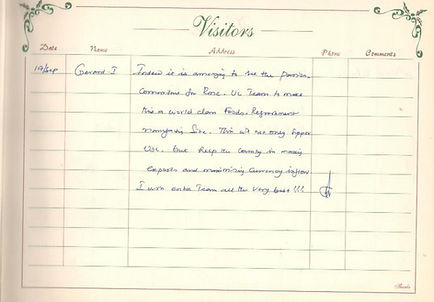

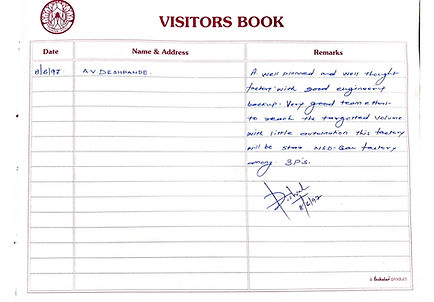

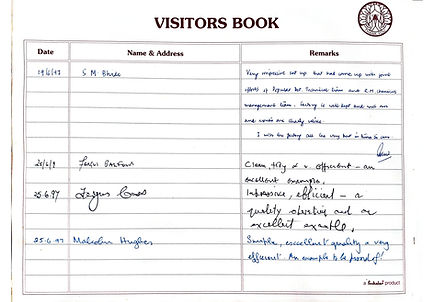

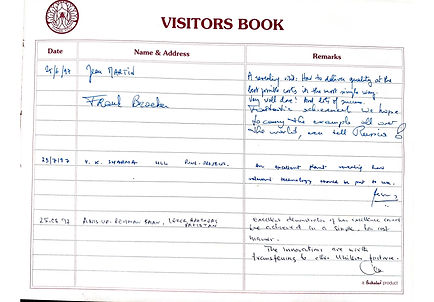

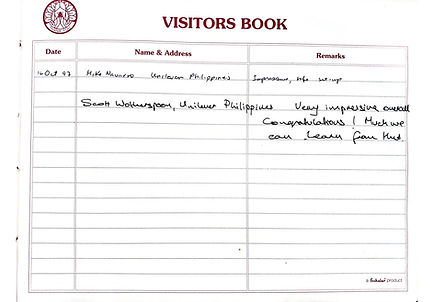

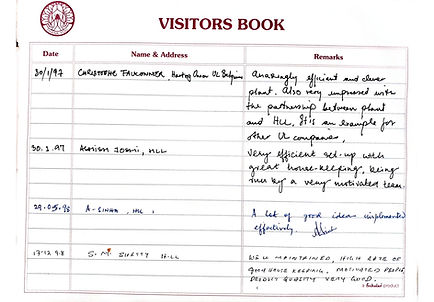

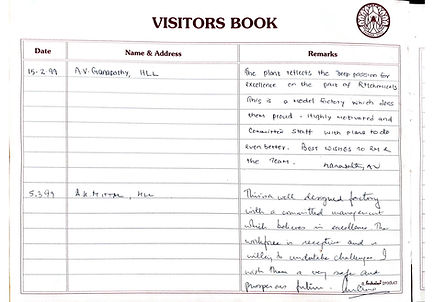

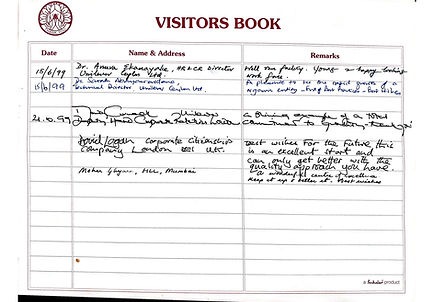

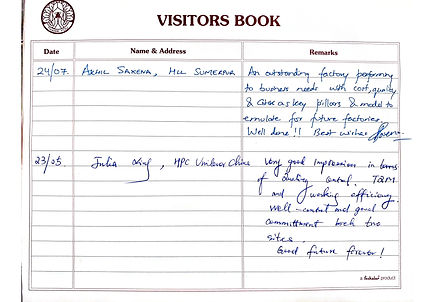

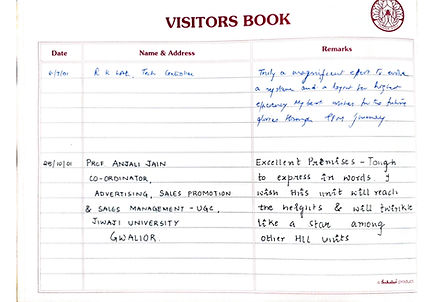

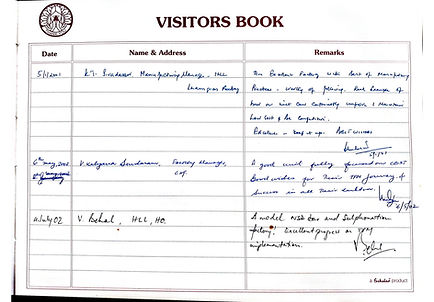

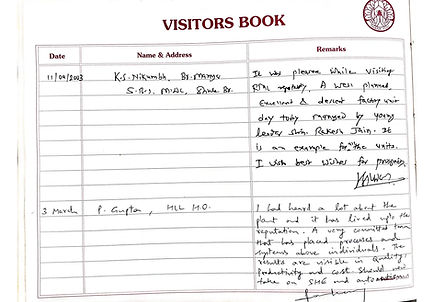

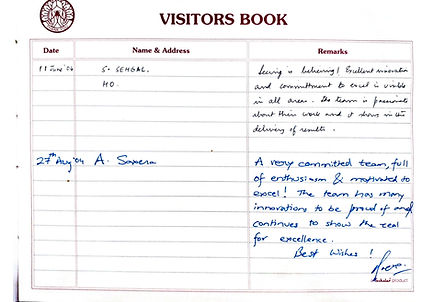

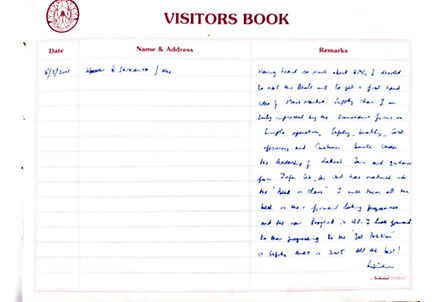

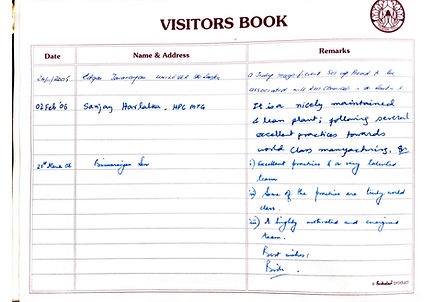

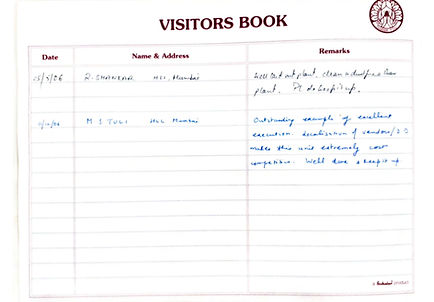

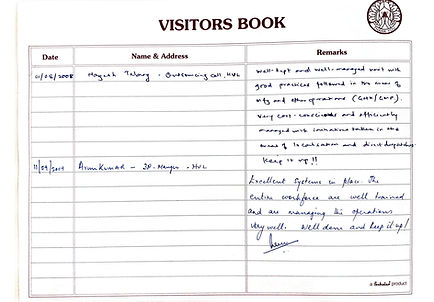

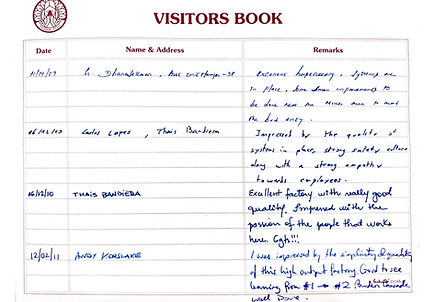

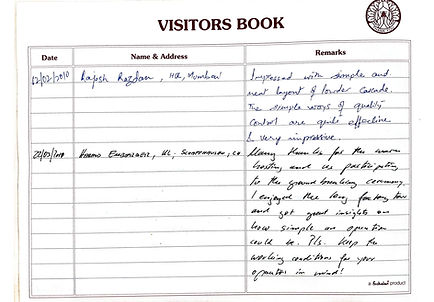

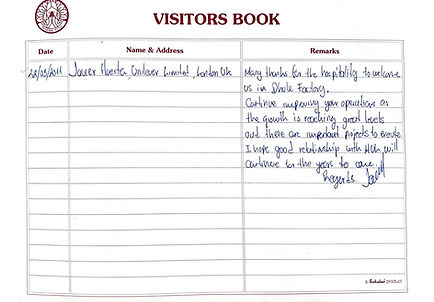

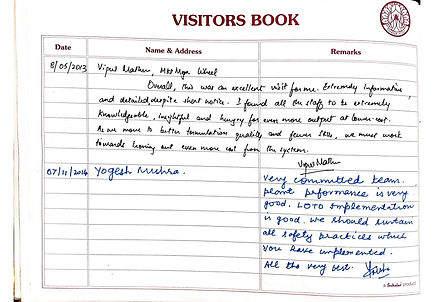

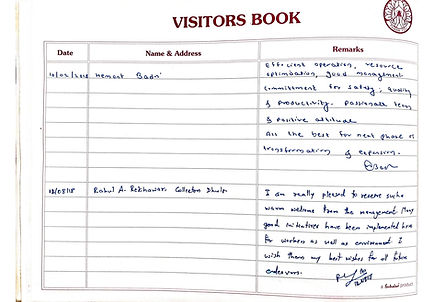

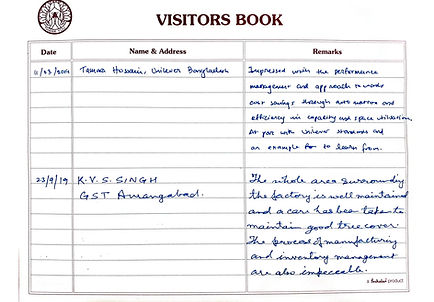

Rakesh remembers a delegation of Lever heads from seven different countries that visited the factory in 1997 to learn how a low cost, good quality non-soap detergent plant could be set up. The visitors’ book shows interest and admiration not only from Indian HUL managers, but also managers from Turkey, London, China and Sri Lanka.

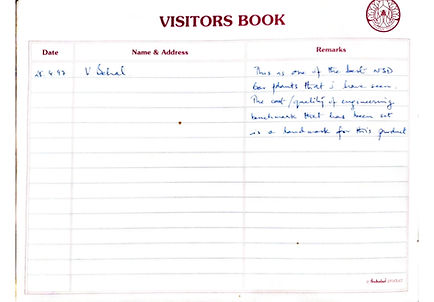

Vidur Behal, who is still with Unilever as Vice President, R&D Homecare for all of Asia, also visited the plant and wrote, “This is one of the best NSD bar plants that I have ever seen. The cost and quality-of-engineering benchmark that has been set is a landmark for this product.”

Vidur Behal, Vice President, Unilever, R&D Homecare for all of Asia - praising Dhulia plant

This success gave Hindustan Lever confidence in the RM Group’s ability to set up an efficient plant, and in the very first year, they were also given the Vim bar to produce. The total sales of Vim so far had not been large compared to their other brands, and sales were just 30,000 tons per annum. The company hoped to increase that number with the bar being manufactured in a more efficient way at the new plant.

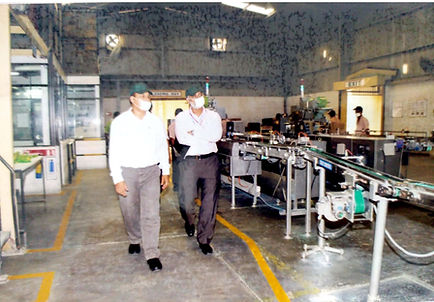

Mr.Pradeep Baneerje’s visit to RM Chemical Ceylon Pvt.Ltd

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

SBI Represenataives Mr.Ramesh Chander and Mr.Dorababu visit to RM Chemical Ceylon Pvt.Ltd

Unilever Delegates Mr.Dhaval Buch and Mr.Ishraq Tahmeem visit to RM Chemical Ceylon Pvt.Ltd

Mr.Shahab Ali, Manufacturing Director USL visit to RM Chemical Ceylon Pvt.Ltd

Visitors Book snapshots from RM Chemical Ceylon Pvt.Ltd

Mr.R.K.Lal and International Delegates of Unilever visit to Dhule Factory

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Visitors Book snapshots from Dhule Factory

This, however, was not a very easy task, as the product’s formulation made it difficult to manufacture bars that set uniformly. Faced with quality issues, the group convinced the Hindustan Lever technical team to re-examine the formula. The company deployed one of their best R & D staff, Dr.Nikhilesh Mukherjee, who spent nearly three months in Dhulia running over a hundred trials on the Vim bar until he finally hit upon the right formula. Magnesium sulphate was replaced by aluminium sulphate, and the consistency of the bars showed a marked improvement.

Rakesh Jain recalls, “The trial bars would be in all sorts of colours – green, pink, red, which caused us consternation for some time. But the level of dedication gave us the confidence of knowing that we could not only handle production but ensure quality, too.”

As time went by, the Dhulia plant was expanded to start a sulfonation plant, where the basic raw material for detergent, linear alkylbenzene sulfonic acid (LABSA) or slurry, was produced. The Hindustan Lever teams placed implicit trust in the RM Group. Typically, in contract manufacturing, producers could fiddle with formulations to save money, leading to an inferior product or skimming of profits. The RM Group never stooped to such levels. They stuck to policy and a code of ethics, and it was understood within their teams that no leeway would be given to anyone who misused their authority.

The plant eventually acquired the contract for Hindustan Lever’s premium white soap, Lux International, which the company rarely outsourced. The RM Group produced it for ten years. Another premium detergent Surf Excel, which HUL also never outsourced, was given to the RM Group in 2012. An amusing story often told is that in 1997, Hindustan Lever established a Best Quality award for all their contract manufacturing companies. The RM Group ended up winning the award four years in a row, so eventually the company decided there was no real contest and discontinued the award.

Expansion and the next generation

Surendra Kumar Jain, Rakesh’s father recalls, “Both Sunil and Surendra were go-getters, very keen to make use of new opportunities. When Hindustan Lever offered us the Sri Lanka project in 2001, half the people here weren’t in favour of taking it on, as the location was far away and out of the country. But Surendra was adamant that we should do it, and so work started in Sri Lanka.”

Mahendra’s eldest son Abhishek, who had by then finished his engineering course, joined the business to look after Sri Lanka operations at the time. Mahendra Jain recalls: “Earlier, Hindustan Lever in Sri Lanka would import Vim bars. So when they decided to start manufacturing locally, the RM Group, with our experience of Vim bar manufacturing were a good fit. Plans were finalised within a week.”

In 2005, a new NSD project was started in Baddi. By this time, the plant in Dhulia was being supervised by Mahendra and Surendra, so Rakesh took over Baddi. The project had initially been set up to manufacture Rin detergent powder. Manufacturing machines were bought in from China and the plant was expanded to make toilet soap as well.

Vim bars and Vim liquid followed, and then Surf Excelmatic, which was the company’s most expensive clothes detergent. The corporate office was set up in Chandigarh in 2017 as well, and Surendra’s son Rishikesh Jain who started from Sri Lanka in 2008, later joined the operations in Chandigarh.

Meanwhile, the Dhulia plant had expanded to 100,000 tons per year. The group was looking to develop this operation further, and so they took over 4.5 acres of adjoining land, taking the total factory area to 8.25 acres. Here, the plant expanded to manufacturing Wheel detergent powder. Capacity In the beginning was 30,000 tons per year, which soon increased to over 200,000 tons.

At one point, the RM Group was manufacturing 300,000 tons of detergent bars, powders, soap, etc. for Hindustan Lever.

Hindustan Lever also offered them an old factory in Hetauda, Nepal, which someone had set up and then not looked after properly. Nepal operations were started under Abhishek Jain, who continues to handle them currently.

In 2020 they were offered a project in the Philippines. After a survey and some discussions over six months, an MoU was signed and the project was given the go-ahead. Currently, the Philippines operation is being set up by Animesh along with Rakesh Jain.

Meanwhile, Sunil has been expanding operations for the agency, adding ITC, Maruti Suzuki and Nexa to their existing brands. A dealership was tried for Indore as well, but it didn’t work out and was shut down after two years.